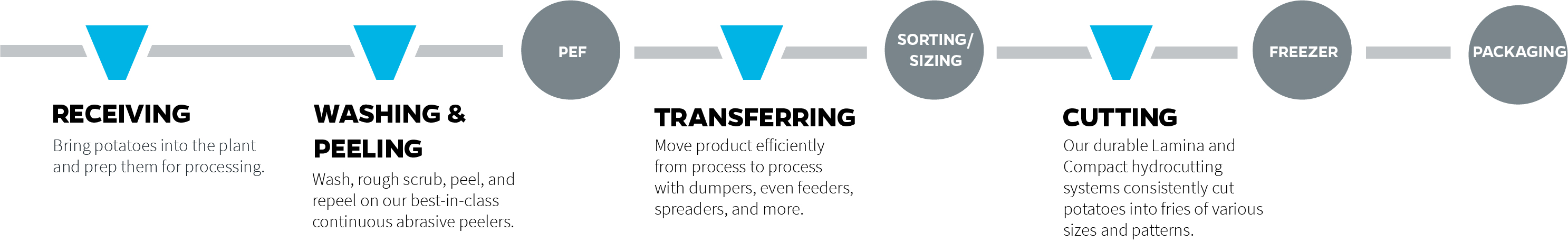

French Fry Production Equipment Line

Vanmark french fry processing equipment supports large-scale receiving, washing, peeling, and cutting processes. Our equipment integrates with other processes, such as optical sorting, seasoning, freezing, and packaging. Each equipment line is custom configured to your plant, layout, production volume, and product mix. See a sample french fry production process below.