Carrot Processing Equipment Line

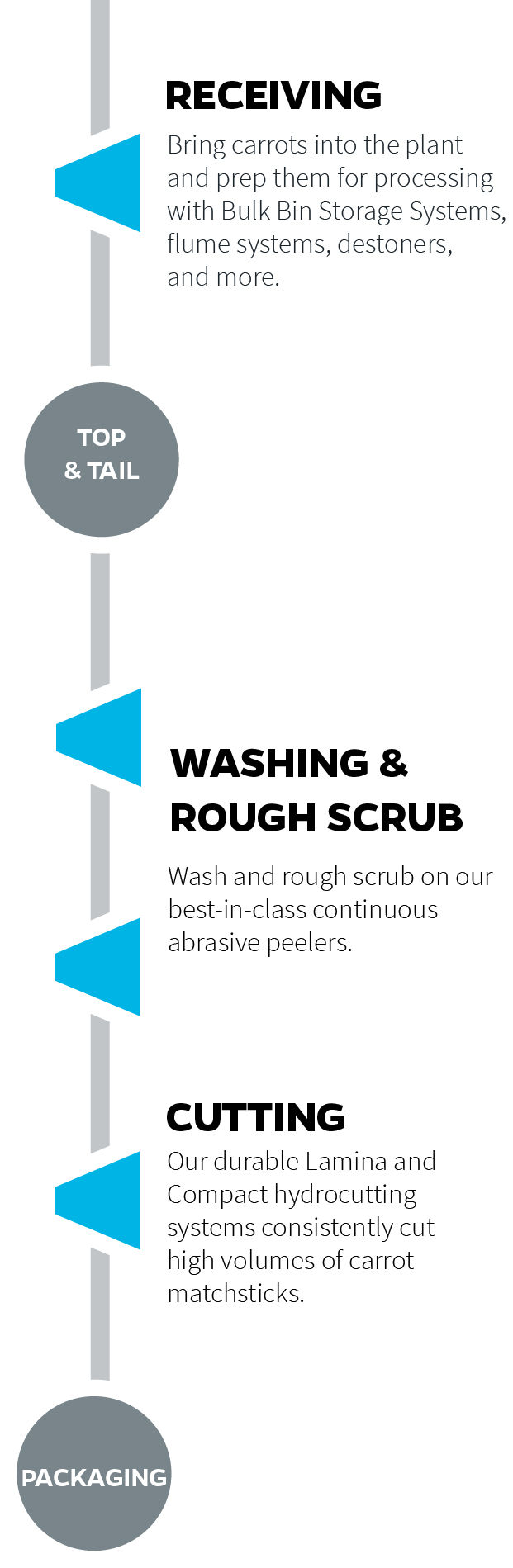

Vanmark carrot processing equipment supports large-scale operations. Our machines integrate seamlessly with other OEMs to automate processing lines for baby carrots, carrot matchsticks, and more. We custom-configure each line to your plant, production volume, equipment layout, and product mix. See how our equipment fits within the general carrot processing process.