304 or 316 stainless steel construction

Product Size

Diameter: up to 4” (102mm) bore

Two to 12 or more cutters

Pump Size*:

6, 8, or 10” pump assembly

*Dependent on product size

Water Capacity:

82 gallons (310 L)

Electrical:

230-460 VAC, 3 Phase (other voltages available)

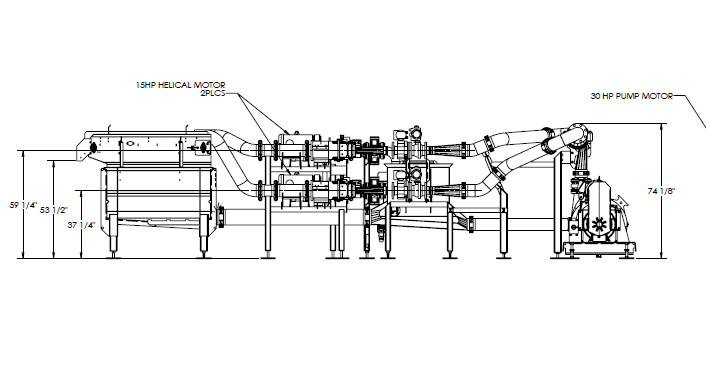

View CAD drawing