Vanmark hydrocutters have a well-deserved reputation for offering durable, reliable, top-of-the-market performance. In fact, we have cutting lines from the 1970s and 80s that are still in operation

Vanmark hydrocutters have a well-deserved reputation for offering durable, reliable, top-of-the-market performance. In fact, we have cutting lines from the 1970s and 80s that are still in operation today.

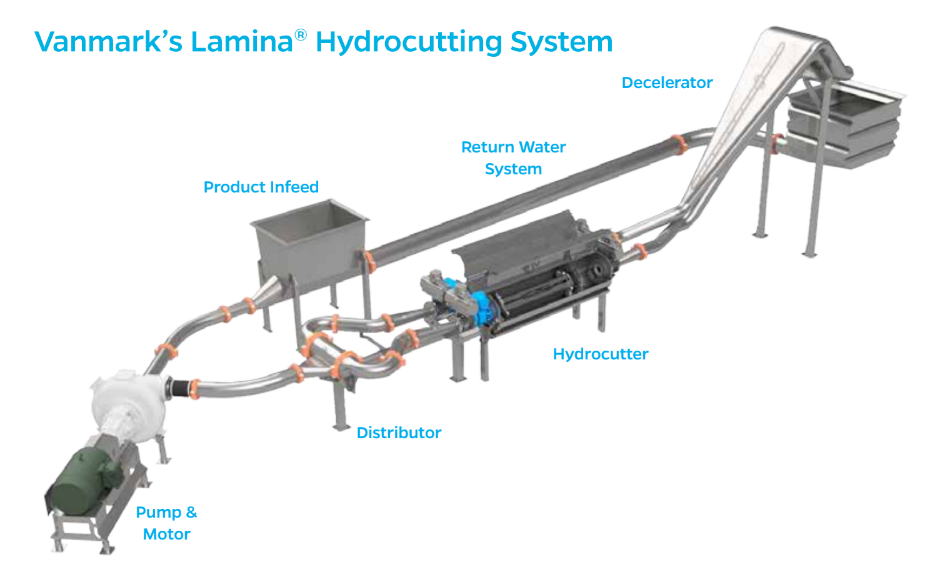

We’ve made major improvements to our hydrocutting systems over the years and decades, allowing for increased performance, sanitation, and reliability. These improvements culminated in the current Lamina Hydrocutting System design.

If you’re currently running an older Centurion or Mark-V hydrocutter, read on to discover the value and benefits you’ll get from upgrading to our modern line of Lamina hydrocutters.

Several Reasons to Upgrade to Lamina

Increase Throughput and Decrease Maintenance

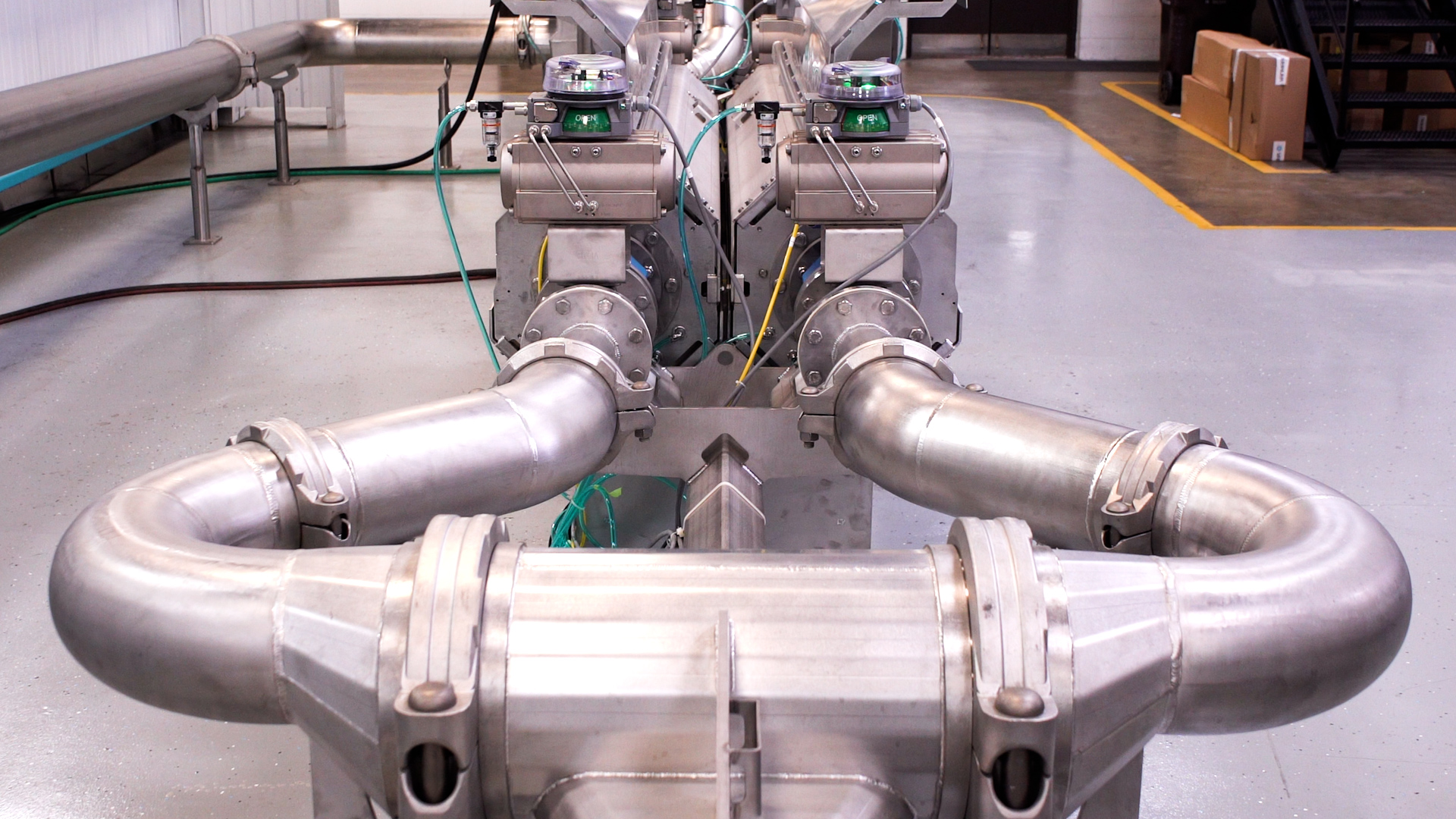

Because the Lamina utilizes a distributor instead of a switcher to load product into the hydrocutter, you have more control over the process.

A distributor divides the product into two outlets, giving you the flexibility to run two hydrocutters at the same time or to switch flow from one to the other. This allows processors to double throughput. They can also switch flow through one side if there’s a blockage or the operator needs to stop the line temporarily. This keeps production running and eliminates downtime.

Durability

The Lamina Hydrocutter was designed to drastically reduce the number of consumable parts over the Centurion. Minimal wear on parts, and limited adjustments all but eliminate maintenance downtime and ensure long-term, accurate operation.

The Lamina Hydrocutter also uses a thick stainless steel for the outer skins. As a result, there should never be any need for replacement of the outer skins on a Lamina, a problem often experienced by older machines.

While each Lamina system is custom-configured to match a layout and application, every system is modeled using CFD-driven analysis to confirm optimal flow, sizing, and performance before system is manufactured and installed – giving you confidence it will perform.

Accuracy

The previous hydrocutter alignment assembly required periodic checks and readjustments to ensure the hydrotube was properly aligned to the blades. The new design on the Lamina is self-aligning, which means you don't have to worry about the accuracy and consistency of your cuts.

Ease of Use

.jpg?ver=5G3Lv9zflqMS0ZPGiBr5zQ%3d%3d) The Lamina includes an updated pneumatic clamping mechanism that utilizes a “one-touch” motion to lock the hydrotube & cutterhead housing into place, which allows for faster, easier changeouts (usually less than 30 seconds). This is a significant time-saver over the Centurion’s manual, crank wheel design.

The Lamina includes an updated pneumatic clamping mechanism that utilizes a “one-touch” motion to lock the hydrotube & cutterhead housing into place, which allows for faster, easier changeouts (usually less than 30 seconds). This is a significant time-saver over the Centurion’s manual, crank wheel design.

Also, the Centurion Hydrocutter required the operator to lift the cutterhead housing straight up and out from above. The Lamina Hydrocutter's design offers access from the side of the machine, allowing the housing to be easily slid in and out of place with minimal strain.

Safety

The Lamina includes locking switches on the doors so that the hydrotube and housing chambers are closed off and inaccessible during operation. This is a significant improvement in safety to the operators.

Servicing older Centurion Hydrocutters

If you’re not ready to upgrade to a new Lamina, Vanmark can also service older Centurion systems. The Centurion features many consumable parts that need replaced regularly to keep the system operating to spec.

Our technical services for older model Centurions include:

- Health checks

- Inspections

- Part kits

- Rebuilds

Our continued support of our older hydrocutter models helps to ensure optimal and reliable performance for many decades into the future.

Request a Consultation

Upgrade Today for Increased Performance and Value

The Lanimna Hydrocutting systems offer decreased maintenance, improved throughput, and a longer lifespan. Click below to learn more about the value and benefits you can expect from Vanmark hydrocutters.

Lamina Hydrocutting System