The potato peeling and cutting processes use a tremendous amount of water. There is an increasing demand for better and more efficient water conservation techniques. The water sustainability burden

The potato peeling and cutting processes use a tremendous amount of water. There is an increasing demand for better and more efficient water conservation techniques.

The water sustainability burden falls on the processors and the manufacturers of the processing equipment they use. We’ve used our decades of experience to find water conservation opportunities throughout our entire line of equipment – specifically peeling and cutting applications. These solutions:

- Recirculate process water

- Reduce water sent for treatment

- Clean peeler beds more efficiently

- Separate starch and solids from process water

Read on to learn more about how we help potato processors with their water sustainability efforts.

Potato Peeler Water Conservation

The waste generated from abrasive peelers contributes to water consumption and treatment costs. At Vanmark, we have worked to develop solutions to help our processors reduce their total water usage and recycle and recirculate their process water.

Water Recycling

Water recycling incorporates capturing water, cleaning it, then reusing it instead of sending it for treatment or dumping it into the sewer system. There are hard cost savings to recycling water - reduced water usage and cost, reduced water treatment costs - as well as sustainability/climate change benefits.

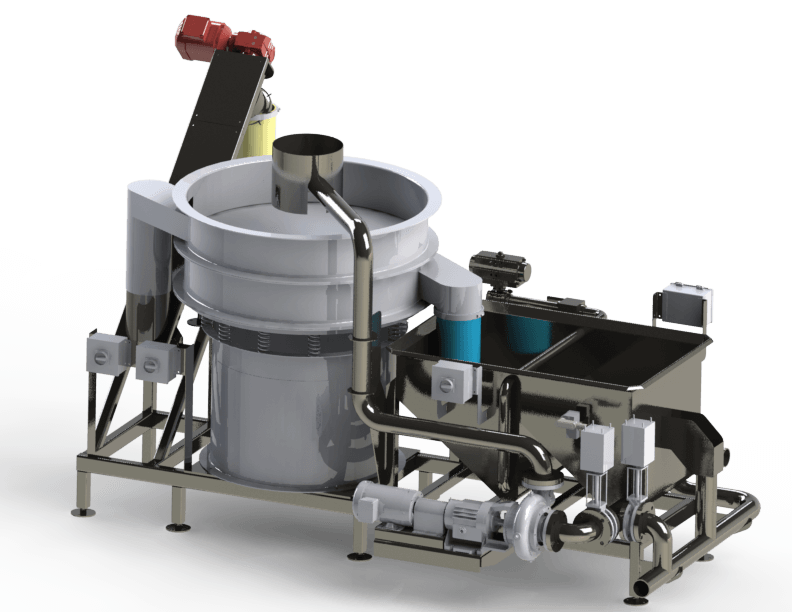

The Vanmark Water Reclamation System

The Water Reclamation System significantly reduces fresh-water usage up to 90% through recirculation. The skid-m ounted system removes the peel waste from the water and then collects it, preventing it from entering the drain.

ounted system removes the peel waste from the water and then collects it, preventing it from entering the drain.

The filtered water is then recirculated back into the peeler through a closed-loop system that significantly reduces fresh-water usage. Effluent from up to 3 continuous peelers collects in a tank. The solids are then run through a dewatering auger that separates the water and solids further. The peel waste gets removed through a self-cleaning screen and is collected. Filtered water is pumped back to the infeed end of the spray bar system at each peeler.

The reclamation system supports up to three Vanmark Peeler/Scrubber/Washer machines, allowing each machine to use less than 1.5 GPM (5.7 L/min) of fresh input water.

Reducing Water Usage

The key to reducing water consumption lies in the processes and equipment used to peel, scrub, and wash potatoes. Vanmark offers several different machines that can significantly cut down on the amount of water used while processing potatoes.

The Peeler/Scrubber/Washer CIP System

The moving CIP spray bar system cleans the peeler bed during operation and at sanitation. It uses upper and lower spray bars to consistently and thoroughly clean every cycle.

The CIP System saves more water than a traditional pan spray setup and reduces the amount of water needed during cleaning and sanitation.

The machine works with all roll types and is compatible with Vanmark 2820/22 and 2920/22 Peeler/Scrubber/Washers, as a retrofit or on new orders.

Separating Solids

Peel solids and skin accumulate in a peeler’s processing water. The amount and frequency of solid buildup depend on the product and volume of your operation. Separating or screening out solid “sludge” from the process water reduces the burden of water treatment.

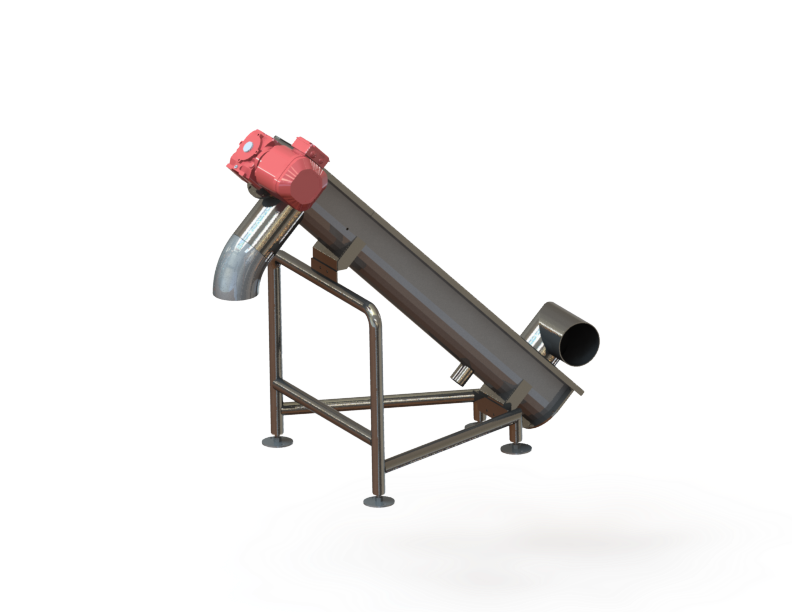

Waste Separating Auger

The Waste Separating Auger screens out these solids, reducing waste that goes into the drain system, thereby lowering water treatment costs.

Generally speaking, the solids output waste of the auger is about 1% of the total potato input to the peeler. For example, if you’re running 10,000 lbs of potatoes per hour, you’ll get around 100 lbs per hour of solid waste out of the auger.

Generally speaking, the solids output waste of the auger is about 1% of the total potato input to the peeler. For example, if you’re running 10,000 lbs of potatoes per hour, you’ll get around 100 lbs per hour of solid waste out of the auger.

The auger supports a single Peeler/Scrubber/Washer and has a small footprint which enables it to be located next to the peeler without impacting equipment line flow. The sanitary design provides for a thorough and quick cleaning process.

Potato Hydrocutting Water Conservation

Hydrocutting potatoes uses a tremendous amount of water. However, there are several ways in which you can reduce consumption by separating starch and recycling water.

Separating Starch

Water that is too starchy leads to significant performance issues. Since it draws in more air, it can lead to more system plugs, additional breakage, and damage to internal components over time. Therefore, removing the starch particles from the hydrocutter system process water is essential.

The traditional process is accomplished by “bleeding out” approximately 2% of water and continually replacing it with clean water. This method could be more wasteful, costly, and not as precise.

Then the water is sent to a Starch Recovery System or a Collection Tank to filter and collect the starch to use in other products or sell as an ingredient - another costly process.

Lamina Hydrocutting System Starch Separator

We’ve added an option to our Lamina Hydrocutting System return water line to increase the efficiency of the starch removal. It creates a cyclone in the line that pushes the starchiest water to the edge of the pipe, then skims that water out. This allows potato processors to reduce the amount of water bled out of the system (and pumped in) while maintaining the right level of cleanliness.