There are many options and decision points to consider when building a peeler to add to your processing line. At Vanmark, we customize our processing equipment and tailor its performance to a specific

There are many options and decision points to consider when building a peeler to add to your processing line. At Vanmark, we customize our processing equipment and tailor its performance to a specific application.

For example, if you’re trying to re-peel, we will select the best parts/options for that particular peeling machine. We custom base everything on your needs—as there always isn’t a one-size-fits-all solution for any specific product or process.

Read on to learn more about industrial peeling processing equipment and the factors that determine their custom configurations.

Important Options and Decision Points

The below questions will help you determine which Vanmark peeler and washer model is right for your application. When you reach out to our customer service reps, they’ll be able to walk you through the selection process and then recommend a machine, roll configuration, and associated options.

Document processes—Write down how you do what you do—then think about your processes. Which ones are you trying to automate? How much product do you run, at what speed, and for how long. How much waste do you create?

Define specs and requirements—What will and won’t work with your operations? Consider equipment sizes, layout, integrations, utility needs, parts schedules, maintenance and sanitation, and accessibility/clearance. The more you know, the easier it is to identify viable options.

Determine your goals—Before you can evaluate potential solutions, you need to understand what it is that you’re trying to accomplish. The end goals of most food processors and manufacturers include increased capacity for a new account or product, improved efficiency, and solving labor issues.

What is your production rate?—How much are you processing per hour? Are you looking to scale up from your current production rate?

Function—What functionality do you need? For example: wash, rough scrub, peel, re-peel, finish wash? Do you need to remove rocks and debris?

Food Application—Are you processing potatoes, cucumbers, french fries, carrots, etc.?

Footprint—Is this going in an existing line? What type of space constraints do you have? That could have an impact on the machine configuration. Other considerations include integrating with other equipment and where the peeler will be on the line—i.e. at receiving vs. after a steam peeler.

Maintenance—What labor capacity does your team have to complete the required maintenance? Do you need a machine that requires less maintenance due to staffing concerns?

Determine your budget—Food processing equipment can be a significant investment. Calculate payback times and ROI to gain the confidence you’re spending your money wisely. Be sure to take labor, maintenance, parts, and utilities into account. We can suggest options and configurations that adhere to your budget.

Research your supplier—There are quite a few industrial peeler and washer manufacturers out there. Look for a partner that demonstrates industry expertise and dependability. Also, consider their ability to provide support throughout the lifetime of the machine.

Roll Types and Configurations

Once a peeler model is determined, we custom-configure the right combination of rolls based on the machine, application, and level of peel you’re looking to achieve.

Our peeler models can range from four to 16 rolls. The number of rolls will change based on the size of the peeler and peeler bed—i.e. Larger machines have more rolls, and in bigger machines, the length of the rolls is longer so that you can fit more product inside and achieve the right peel level at a higher volume.

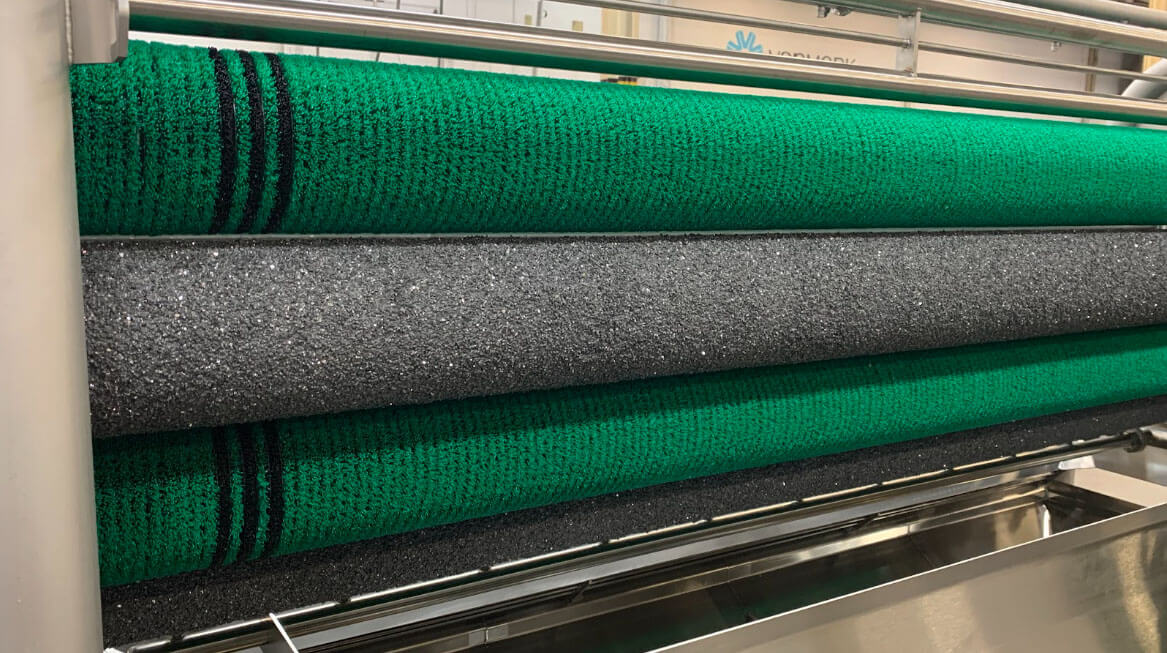

Typically we recommend multiple types of rolls in each machine, from the following:

- Brushes—wash, peel, and scrub the product as they remove dirt, debris, and the desired peel level without losing yield.

- Coated Abrasive—these peel, polish, and rough scrub the product and leave a smooth surface.

- Lift Roll—this smaller diameter roll tumbles the product and separates solids while keeping the chamber cleaner after steam peeling.

- Rubber Pintle—collects loose residue after steam peeling to keep the peeler clean.

- Sinewave Segment—this roller is mechanically timed to synchronize segment movement to abrasively peel odd-shaped products.

Discharge

The discharge is where the product comes out of the machine, and it determines the length of time that the product stays inside. We can adjust this so that the product remains in longer if you want to peel the product a lot more, or you could adjust it lower so that you only get a rough peel if that’s what you need.

Vanmark Peeler/Scrubber/Washer CIP System

Our Peeler/Scrubber/Washer Clean in Place (CIP) System reduces manual cleaning and downtime by cleaning the peeler rolls and bed during sanitation and production. Cleaning cycles are as short as 7 minutes. The CIP system is a highly effective and efficient solution to keeping your peeler clean. Click below to see the CIP system in action:

Vanmark Custom Peeler Processing Equipment

It’s essential to have the right peeler equipment configurations to ensure maximum efficiency while minimizing waste and downtime. Click below to learn more about our industrial potato processing equipment.

Potato Processing Equipment