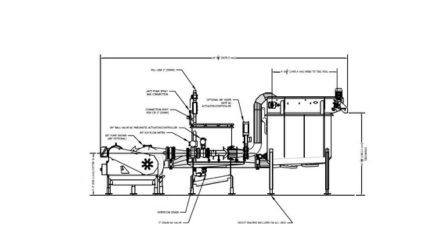

System Dimensions

230” L x 80” W x 92” H (5842 x 2032 x 2337mm)

Product Size

Diameter: up to 5” (127 mm)

Length: up to 6-12” (152-305 mm)

Pump Size*

6, 8, or 10” pump assembly

*Dependent on product size

Water Capacity

350 gallons (1324.89 L)

Electrical

230-460 VAC, 3 Phase (other voltages available)

Motors

Pump motor: 30-50 HP

Conveyor motor: 0.25-0.5 HP

View CAD drawing